Digitalisation and artificial intelligence are becoming increasingly important, not only in everyday life, but also in manufacturing. These modern tools can also be used for industrial applications. As a leading manufacturer of CNC machine tools and manufacturing systems, HELLER early on recognised the importance of digitalisation and AI. Several years ago, the company formed a cross-departmental team of specialists dedicated to these fields. Working closely with external partners, this team has developed solutions aimed at making machine operation more efficient and enabling predictive maintenance and production planning. Dr Thorsten Schmidt, CEO of HELLER, is a key supporter and driver of this initiative. He emphasises: “We are focusing on three key areas – machine operation, maintenance/service and production planning – where AI delivers real benefits and boosts our customers’ productivity. At EMO 2025, the company will present practical applications and the concepts behind them."

Process-orientated assistance – digitally supported

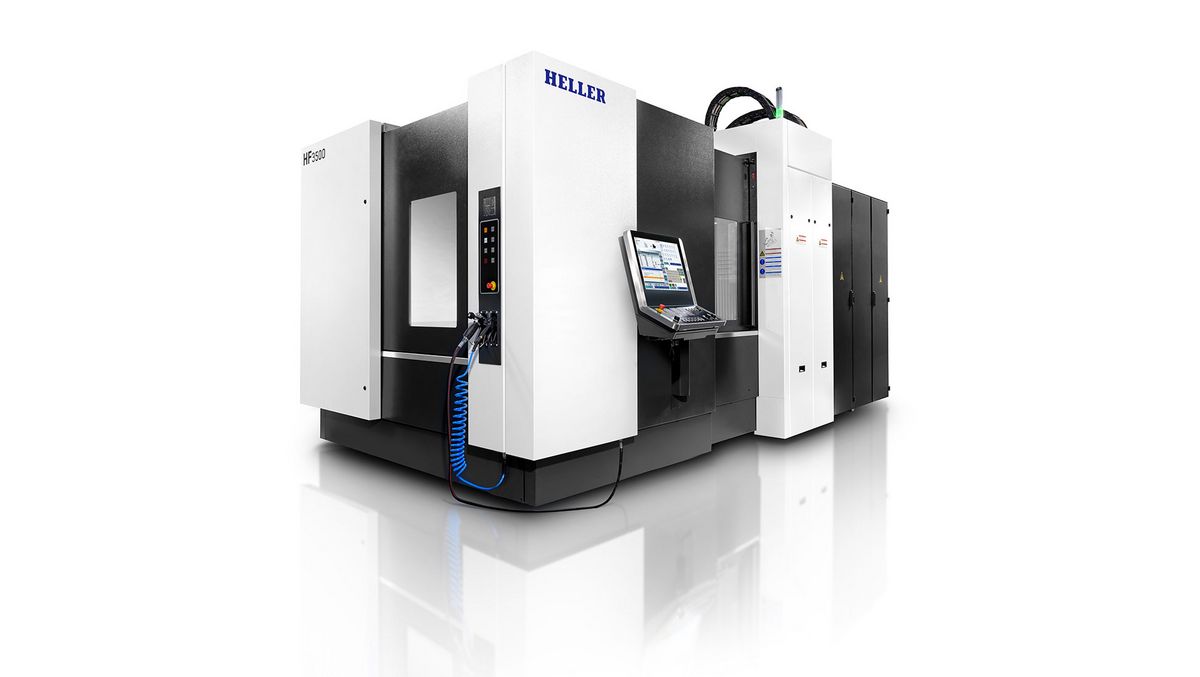

Two state-of-the-art 5-axis machining centres – an HF 3500 and an F 5000 – will be on permanent display and will be cutting material live throughout the event. On these machines, HELLER will also demonstrate how operators are digitally supported throughout the entire process chain. During setup, operators are supported by the ‘SETUP-Assist’, throughout the manufacturing process by the ‘PRODUCTION-Assist’, and – to ensure component accuracy – by the newly developed ‘QUALITY-Assist’. But that’s not all. By measuring temperature rises in the spindle, even the slightest length expansion can be calculated and compensated for. This allows the machine to maintain maximum precision and productivity without any additional operator intervention.

Smart & data-driven – AI in process and analysis

A brand-new feature to be introduced at EMO 2025 will provide customers with access to an intelligent chat function called “ASK-me”. This tool, integrated into the machine control interface, offers operators a ChatGPT-like assistant. In other words: users can enter questions in plain language, and the AI function quickly delivers clear, straightforward answers. The AI assistant uses the collective expertise of HELLER and its users to provide answers and support relating to the handling of the machine, including operation, setup and maintenance, and helps to interpret warning and error messages based on the machine’s live status. HELLER will also showcase AI-powered analysis tools at EMO, offering valuable benefits for maintaining productivity and high precision of modern machining centres. To achieve this, the Nürtingen-based machine manufacturer uses data collected as part of its Industry 4.0 strategy. The data can be visualised by production planners and analysts via the shop floor system – the HELLER Services Interface – in the form of text, tables or diagrams. This ensures transparency throughout the entire lifecycle of the machine – in production, maintenance, and service processes. For instance, hidden machine downtime can be identified using a generatively produced chart visualisation, whilst AI-supported analysis of the production data helps to reveal potential for boosting output.

At the trade fair stand, the HELLER service experts will demonstrate how the combination of data acquisition and intelligent analysis provides key insights for preventive maintenance. Returning to the previous example of the HELLER spindle: run times, load and overload phases and spindle speed values are also routinely recorded in addition to temperature trends. Based on this, it is possible to monitor the spindle’s condition and to prevent unplanned machine downtime caused by wear-related failure of the spindle. The same principle applies to other components such as axes or tools.

Simultaneous 5-axis machining in different configurations

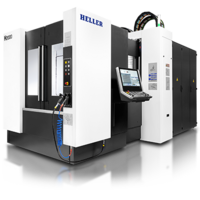

In addition to the digital highlights, HELLER will showcase its extensive engineering expertise at EMO 2025 with two 5-axis machining centres. The HF 3500 stands out thanks to its table kinematics featuring counter bearings as standard, as well as its high dynamics and short non-productive times. The PRO version of the machine on display at the trade fair stand features a Z-axis driven on both sides and comes equipped with all the necessary functions for perfect simultaneous machining. The high acceleration rates of 10 m/s2, axis speeds of 90 m/min and extremely short chip-to-chip times are also advantageous. HELLER’s high-performance spindle, featuring the proven zero-spindle system, ensures maximum productivity. Its combination of high torque and speed makes it ideal for a wide variety of applications.

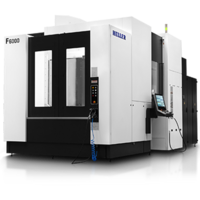

The F 5000 with head kinematics is used for the machining of heavier components. It is distinguished by its numerous features and key components, including a motor spindle with an HSK-A 63 tool interface. Due to its modular design, the F 5000 can be optimally configured for a diverse range of applications, always ensuring maximum precision and performance in the production of small to medium batch sizes. Thanks to its tilt head, this machine is especially flexible and extremely well-suited to the machining of undercuts and recesses. These machining capabilities are essential, for example, for the manufacture of integral components in the aerospace industry.

The latest automation options for workpiece and tool handling

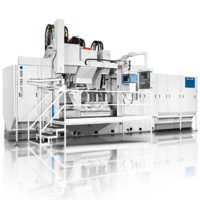

Another innovation of interest to companies producing constantly changing workpieces within a production cell is the ‘Robot Cell Professional’, or RP4 for short. It will also be showcased at EMO 2025 where it is docked to the HF 3500, as an example. It can also be used in combination with the HF 5500 and the 4-axis H series. As a standardised robotic automation solution, it offers a highly flexible range of applications thanks to its multi-batch capability. It can load and unload the machining centre in any order and handle different workpieces and pallets including clamping fixtures. An integrated digital twin enables the RP4 to be set up in parallel with machining. With appropriate workpiece provisioning in place, unmanned shifts and fully autonomous weekend operation are possible.

Also interesting: at the trade fair, HELLER will demonstrate how quickly and easily tools can be changed in batches using a newly developed rack-type tool magazine, including a mobile rack, connected to the 5-axis machining centre F 5000. With this type of automated tool changeover, several worn tools are removed from the machine together (in one cassette) and replaced with new tools that have been prepared in the setup room and placed in the mobile rack.

Thanks to their slim design, the new rack-type magazines offer an optimised footprint and can store up to 340 HSK-A 100 tools or approx. 490 HSK-A 63 tools. The version with 260 storage places will be on display at the trade fair. The optional mobile racks can be combined with all sizes and can also be fitted with their own drive for fully automatic operation. This enables the automated transport of tools to and from the machining centre, which frees up the operator and saves valuable working time.

Trade visitors to Hall 12, Stand C 70, will experience how HELLER combines digital intelligence, automation and modern machine engineering to increase efficiency, safety and productivity in manufacturing. Register here to receive your complimentary day ticket.